File Name: Decision Analysis – Economic Order Quantity and Inventory Reorder Point

Location: Modeling Toolkit | Decision Analysis | Economic Order Quantity and Inventory Reorder Point

Brief Description: Computes the optimal order size and optimal inventory units to hold that minimize total cost and maximize profits using the EOQ models

Requirements: Modeling Toolkit, Risk Simulator

Modeling Toolkit Functions Used: MTZEOQ, MTZEOQOrders, MTZEOQProbability, MTZEOQReorderPoint, MTZEOQExcess

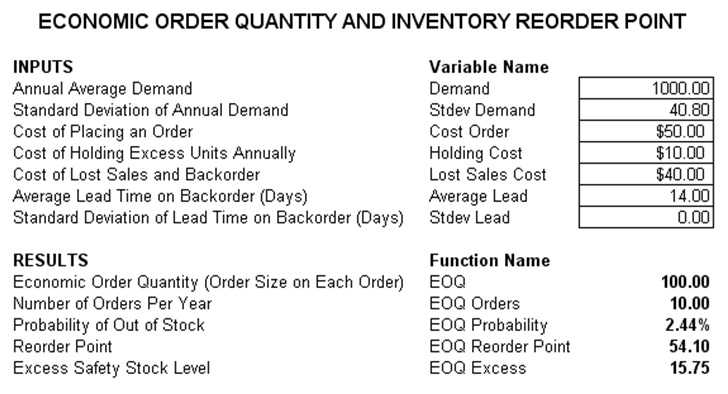

This model illustrates the theory of Economic Order Quantity, or EOQ, which is, in essence, an internal optimization model to determine the best time and the optimal amount to order given levels of demand, uncertainty in demand, the cost of placing new orders, the cost of holding on to obsolete inventory, backorder requirements, and service level requirements. Each of these inputs can be simulated (i.e., set as input assumptions, and the resulting values set as forecasts). The model is fairly self-explanatory. The results obtained tell the store manager how many parts to order the next time an order is placed, the approximate number of orders per year of these many parts, the probability that the part will be out of stock, the reorder point (when inventory on hand hits this point, it is time to reorder) and on average the excess number of parts available (safety level) even with the highest levels of demand (Figure 25.1).

Figure 25.1: EOQ model and inventory controls